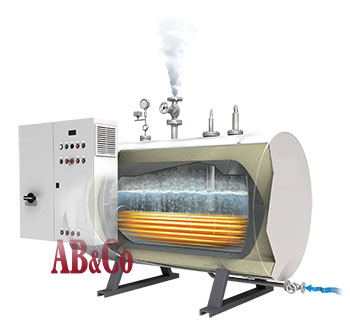

ELECTRIC STEAM BOILER

Introduction to Electrical

Heated

|

|||||||||||||||||||||||||||||||||||||||||||||||

| QUICK ENTRANCE |

| Boilermaker | AB&CO (Copenhagen, Denmark) |

| Models |

Small Vertical Types Larger Horizontal Types |

| Steam Capacities | Up to 5.000 kg/h (3.200 kW) |

| Operational Pressure | Typically up to max. 20 bar gauge |

| Energy Source | Electrical - Voltages up to max. 3 x 690 V |

| The Product | General Description |

| Dimension Guidance | Sketches - Horizontal & Vertical |

| Data & Size Guidance |

Smaller Steam Boilers Large Steam Boilers |

| Special Design |

Mobile Steam (skid-mounted and in container) High Pressures (for high operation temperatures) Clean Steam (comprising culinary steam) Steam Blocks (modular electric steam boiler solutions) |

|

The STANDARD Steam Boilers |

Steam Boiler

Range with Specific Data All THE STANDARD boilers - range & data |

|

Introduction to Other Steam Boilers |

Compact

Steam

Generators

(for oil/gas) Fire-Tube Steam Boilers (for oil/gas) High Pressure Water Boilers (for oil/gas) |

|

Heating Methods |

Steam Generators VS

Steam Boilers Thermal Fluid VS Saturated Steam |

| Assistance |

Design & Trouble Shooting Supervising & Service |

|

Steam Table |

in Saturated Condition |

|

Data Sheet |

Introduction |

Technical TechnicalAssistance & Tools |

Extract

of Extract

of References Worldwide |

|

LOWEST COSTS IN THE LONG RUN ! The key argument for buying and investing in an AB&CO solution. Low total life-cycle cost (LCC) is guaranteed, since LCC include not only purchase, but also operation and maintenance cost, and a life-time of many years. On top of this comes the environmental features that meet the future demands - Sustainable Process Heating |

|

Vertical types Up to 156 kW |

|

||

|

Horizontal types 190 - 1.000 kW |

|||