The Theory of Producing

Steam

Steam and water vapour are actually the same. The term 'Steam' is used more

along with the process application, whereas the term 'Vapour' or 'Vapor' is

the theoretically used general term for gaseous matter generated from

liquid (or solid) phase.

Water and steam are often used as

heat carriers in heating systems. It is known to everyone that water boils

and evaporates at 100°C at atmospheric pressure. And it is also common

knowledge for most, that when exposed to higher pressure, water evaporates

(and eventually condensates also) at corresponding higher

temperature.

This means that the water molecules are suppressed and

retained in liquid form by higher pressure, even when the molecules

increase their internal velocities and thus level of energy (by higher

temperature). For instance a pressure of 10 bar gauge (11 bar

absolute) equals an evaporation temperature of 184°C. These temperature /

pressure relations and other thermal properties appears from a so-called steam table

(see below pdf-file).

AB&CO Steam Table

AB&CO Steam Table

During the evaporation (and condensation) process the pressure and temperature are

maintained constant (isobaric).

During this thermodynamic phase a substantial

amount of heat are use for bringing the water molecules in higher speed, and

thus from liquid phase to be released - a take-off into a kind of a

released "flying" vapour phase.

At this process the steam is "wet" in different degrees until all

water particles

are vaporised - and

the steam is then defined as in dry-saturated condition. It is just being 100% evaporated,

but not in a superheated condition (beyond evaporation temperature) as common known gaseous matter

are at

normal known temperatures (like for instance air and natural gas).

At this

point - the dry saturated condition - the steam

contains a huge amount of so-called latent heat, that corresponding the heat that was

provided during the

evaporation process. This heat correspond the energy of all the released

gaseous water molecules, moving at high velocities and thus with a high

content of energy.

If you heat the steam further from the dry saturated

condition (100% gaseous fluid) - then it becomes

- as previous mentioned - so-called superheated steam, and actually it

becomes an ordinary gas like air and gas, that can have any

temperatures independent of the pressure - and where heating just makes the

molecules moves faster and energy level increases, at same pressure

(isobaric).

In other words and in short, - despite temperature and pressure being constant in the

start and in the end of the evaporation (or condensing) i.e. for the liquid and the vapour

respectively, the amount of heat is very much higher in vapour

phase compare to the

liquid phase.

This retained and potential energy is called 'latent heat', and in the dry-saturated steam

(steam at boiling point) this thermal energy can efficiently be

utilised in

different applications for instance process heating.

Superheated steam

- on the other hand - is mainly used for high performance thermo-dynamic processes e.g.

to drive a steam turbines.

However slightly superheated steam is

often used in process heating in order to compensate for heat loss in steam

piping - and thus to ensure that the steam does not become wet but stay as

high quality dry saturated steam at the location where you need to use it.

Only boilers for saturated steam and steam heating systems are discussed in the following. Boilers

and systems for

superheated steam for other different thermo-dynamic applications is quite a

different subject that is covered by other literature.

The Steam Supply

In steam heating system, the steam boiler

(including the steam generator boiler) is connected to the consumers by

the steam and condensate piping. When the steam is applied to the

consumers, it condensates and thereby releases a high amount of latent heat

described above. The condensate (which is hot water) can then be returned to the feed water tank,

- from where it

again is pumped and provided as feed water to the steam boiler / steam generator. However sometimes the

steam is taken out of the system and consumed in an open system - for instance

when the steam is injected

into a product or in other way discharged or sprayed out (e.g. steam

cleaning or humidifying of air).

So in the closed system, the steam condensate is

returned to

the condensate tank and to the feed water tank respectively. Since steam

pressure in steam heating applications are normally quite high (beyond atmospheric pressure) a pressure reduction

in the form of a steam trap or orifice must be established at the condensate

outlet of the consumer(s) - i.e. before the condensate is eventually returned to the

feed water tank

(which are normally atmospheric or low pressurised) and the steam boiler.

Due to the above

discussed thermo-dynamic relations, this pressure drop causes a generation of flash steam - typically just after the steam trap(s) after the

consumer (whether it might be a heat exchanger or a vessel of any kind).

This gives the well-known large "condensate heat loss" in the steam system,

i.e. high-energy flash steam being generated and

quite noisy led into the condensate line and back to the atmospheric tank where is

steamed up into the ambient.

This mass loss of flash steam also represents corresponding physical and expensive loss of the feed water

content, which then requires

constant amount of fresh and pre-treated make-up feed water added to the circuit. The higher

the steam

pressure is, the higher the heat loss becomes (equals higher demand for expensive new

treated boiler feed water).

We are not speaking moderate losses, but losses between 10 and 30% - in both

heat energy loss and loss in expensive treated feed water ! This phenomenon is the huge disadvantage using steam

for heating - and today is is more or less required that you therefore

invest in flash steam heat recovery solutions when designing and adapting the steam

system into the relevant application processes.

The heat and feed water losses can not only be reduced, sometime its fully

eliminated by investing in "smart" heat recovery features, preferable

integrated in the complete heating system design.

Also other solutions can

minimise these losses, for instance free-circulation steam system,

where you utilise a static height and gravity in a self-controlled

evaporation-condensation-loop, but it can only be used in small and

quite tall systems on local spots - not large steam distribution systems.

The Steam Boiler Operation Principle

"Demand & Delivery"

Any steam boiler works in the principle the

same way.

A typical misunderstanding is that you control the production rate on a

steam boiler. This is not correct.

A steam boiler delivery exactly what is being

consumed in the system The steam boiler is always set for a specific steam

pressure, and the operation of the steam boiler is solely controlled by

means of this steam pressure set point.

The consumer in the system calls for steam by

the decreasing steam pressure since too much steam is condensed at the

consumers compared to what the steam boiler actually delivers.

The reduction

of steam pressure in the system is consequently detected by the control and

the pressure sensors in the steam boiler, which initialise heat (more heat)

in the boiler for evaporating more steam.

When sufficient steam flow

seems to be established, you will have a balance with the consumption of

steam (consumers of the system) and the steam pressure will return into a

stabile condition. |

When the consumers eventually stop demanding steam, the steam pressure

starts increasing - and this detected by the steam boiler control too, and

the heat for evaporating steam is then being turned down to a lower level

where the new balance will be established.

A steam boilers does not work like a machine. It does not impose steam to

the system, it only compensate the lack of steam that is being consumed by the

system.

A steam boiler is an autonomic device. It is purely self-controlled unit and

must thus never be manually controlled by others from safety reasons.

The Alternative to Steam

An

alternative to steam for heating purposes, to use a heat carrier

without evaporation and condensation. Most known is of course a conventional

hot water system. However fr industrial processes another more interesting

alternative is

HEAT TRANSFER FLUID (HTF) - a special

thermal oil where you can operate atmospheric (unpressurised) at

temperature above

300°C. This is however a complete different system, and you cannot just use

- or for that matter exposed - your existing steam system to another heat carrier like thermal oil.

You can

get more information on this subject using this link :

THERMAL

FLUID OIL VERSUS STEAM.

Steam Generator

Boiler

versus

Classic fire-tube Steam Boiler

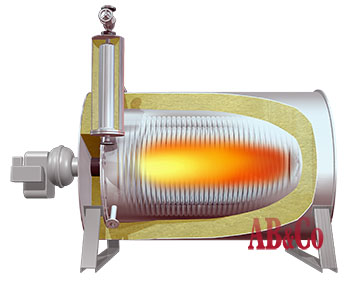

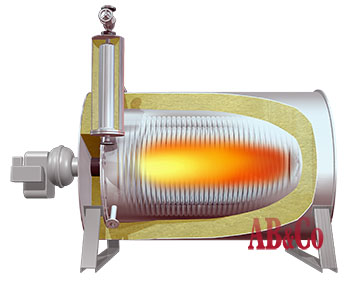

THE PRINCIPLE IN THE FIRE-TUBE STEAM BOILER, is that from the surface of a large volume of feed water, steam

is evaporated. This boiling process is heated by the wall of the combustion

chamber (the radiant part) and by the exhaust gasses passing through a

bundle of so-called

fire-tubes or smoke-tubes forming the the convection part of the boiler.

|

Steam Boiler

Operation

AB&CO

animations

for PC and Smartphone |

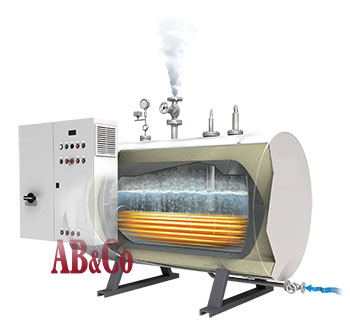

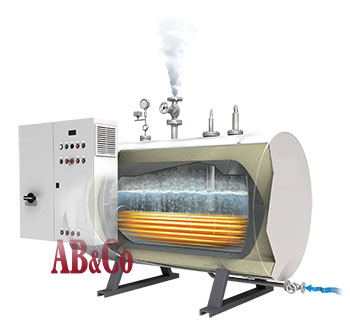

In the so-called steam generator boiler the

operation is quite different. The feed water

and steam are in the principle passing through one long tube - designed as

a number of winded-up tube coils that are being serially connected.

Horizontal or Vertical Design

In this long tube of tube coil assembly, the feed water is heated up to the evaporation temperature

in the first part of the tube coil

and then evaporated in the second part. The intensity of the heat, the feed water flow and the size/length of

the tube are adapted, so that the water is just about being fully evaporated at the exit of the

tube. This ensures a very small total water and steam volume i.e. a small pressure vessel.

There are no extra volume of water at boiling point forming an

evaporation buffer in a steam generator, - and is the steam generator temporary overloaded beyond

its nominal steam capacity, it will gives a operation failure due and alarm

for high steam temperature (superheated steam). The solutions to prevent

this are often just to place a pressure sustaining valve in the steam

line. This valve will protect the steam generator against critically low

steam pressure due to uncontrolled high steam consumption beyond its max.

capacity. But another solution used is to install and connect a separate buffer tank next to the steam

generator that absorb a majority of steam pressure fluctuations (the demand

for extra steam buffer occur in about 10 - 15% of all installations). This

will give some of the advantages of the fire-tube steam boiler. The

ultimate alternative solution is of course to install a real fire-tube steam boiler

instead, - less sensitive to steam pressure

fluctuation (fluctuation is steam consumption).

The

Advantages using a steam generator compared to fire-tube steam boilers

are:

|

Steam Generator Delivery & Options

Steam generator boilers can be delivered in horizontal execution (with low

height), or in vertical execution (occupying limited floor

space). Like the fire-tube steam boilers they are delivered insulated with stainless steel cover

sheets and complete with burner, armatures, instrumentation, safeties and a control panel

- and with full documentation including necessary certificates.

The steam generator boilers are made with coils made

of seamless tubes, where the feed water is preheated and evaporated

during the flow through these. The heat is transferred to the

water/steam mixture as radiant heat in the combustion chamber, where

the inner cylindrical tube coil and a flat tube coil forms the

chamber wall and the bottom respectively. Consequently refractory

concrete at the end of the combustion chamber is avoided. The

combustion gasses are hereafter cooled in the outer convection part,

as the gasses pass the space between the two tube coils.

The thermal design of the steam generator ensures a modest volume of

steam relative to the size of the heater, and allows unlimited thermal expansion due to

the high temperatures. All steam generators and steam boilers must in Europe

be

designed and equipped according to European regulations including EU's

pressure equipment directive PED 2014/68/EU code and EN-standards for steam

boilers.

Electrical Heating - Option of the Future ?

Today there is an increasing demand for

ELECTRIC STEAM BOILERS. Particular the small sizes (up to 250 -

300 kg/h steam) are very popular. They are typically very price

competitive and very easy to install. No chimney and no fuel arrangement

- and very clean. They are today considered environmental

as electricity in many regions increasingly comes from non-fossil energy sources. But

often the electricity is both very expensive in consumption (kWh) since

price for distribution of electricity and taxes are still very high

worldwide. But also if a complete new larger size electrical supply must be establish

to obtain the requested steam capacity.

Rule of thumb is that each kg/h steam requires 1 Amp (@ 3 x 400V).

Electrical Steam Boiler - Industrial Design

Electrical Steam Boiler - Commercial Design

Optional Steam

Boiler / Generator Design

Beside the standard execution the

steam generator boilers can be delivered in for instance following variations:

Exhaust Gas Steam Boilers

Steam can be produced

not only by oil/gas-fired burners and by electrically heating. The steam

boilers can

also be design as so-called recuperators utilising the

substantial amount of waste heat in for instance hot flue gasses or exhaust air. The

steam evaporation is done like the steam generators, and are gives

therefore a rapid acting and compact unit.

These are called

EXCHAUST GAS STEAM BOILERS (EGSB) or exhaust gas steam generator (EGSG).

Economiser using up to 5 heat sources

and extractable / replaceable inserts

A heat exchanger utilisation the waste heat in flue gas of

the steam boiler or steam generator itself for increasing the boiler

efficiency, is called an

ECONOMISER. It can be used for preheating the feed water, but also for

external purposes including preheating of make-up water, domestic water or

central heating water.

|

Important Legal

Announcement

This article including all illustrations are

made by AB&CO and must be considered legally as property of AB&CO. It

can freely be referred to, but must not be copied in

parts or in whole without written permission by AB&CO Group.

Latest revision :

Copenhagen, 8th February 2021

by Arvid Blom,

Senior Engineer & Partner |

|