|

MOBILE STEAM

Introduction to Compact Steam Boilers

|

|

|

| Boilermaker | AB&CO (Copenhagen, Denmark) |

| Models | Electric or with Oil/Gas-Burner |

| Steam Capacities | 70 - 3,000 kg/h |

| Working Pressures | 3 - 30 barg (190 barg w. burner) |

| Energy Source (fuel) | Electrical Heating Elements - or Fuel oil and gas burners. |

|

Efficiencies (DT &

L-DT): The utilisation of Energy depends on actual working loads and steam pressures. |

>99% (Electric) 96 - 98% (including economizer) Designs for extreme high efficiencies provided on request. |

| Examples of mobile steam | General Description |

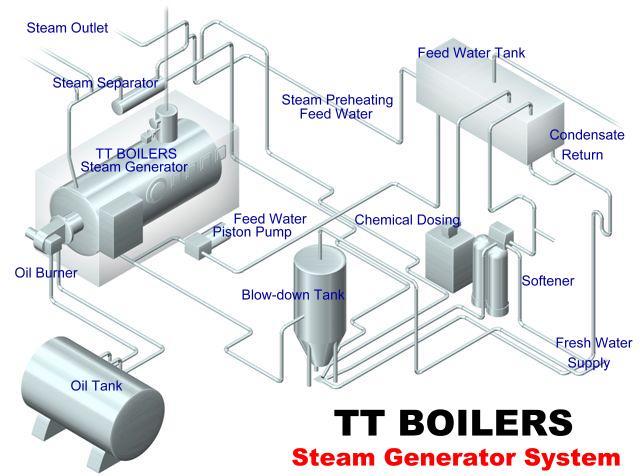

| Steam System | Illustration & Diagram |

| The Basic Boiler - Alternative 1 | Oil/Gas-fired Steam Boilers |

| The Basic Boiler - Alternative 2 | Electric Steam Boilers |

| Heat Recovery (DT & DTM) | 'Economisers' (flue gas) |

| Flue Gas Data (DT & DTM) | Data & Calculations |

|

' Steam

Table ' Saturated Steam Properties |

|

|

AB&CO are a well-known Danish steam

boiler manufacturer, who have specialised in customised solutions

including mobile steam boiler units and steam containers.

The Mobile Steam Boilers are delivered as either as customised

portable solutions in containers or as build-up on a

skid-mounted frame. |

Electric steam boiler arrangement - in container

Oil-fired steam boiler arrangement - in container

Electric steam boiler arrangement

- skid-mounted

Oil-fired steam boiler arrangement

- skid-mounted

|

|

|

Detailed Description of Mobile Solutions

|

|

|||||||||||||||||||||||||||||