|

Steam Heating and High Pressure

Water and steam are typically used as heat

carriers in industrial heating systems.

In industrial heating

systems a high temperature level is often a necessity for achieving the

required high efficiency.

When using steam (or water) these high process temperatures are achieved

by pressurising the steam (or water ).

Dry saturated steam is both very efficient

to carry heat and to deliver and transfer the heat. Saturated steam

offers a very high specific heat content (kJ per kg steam) and thereby

deliver a large amount of heat by a modest steam flow. It also very

efficiently find its way to the heat surfaces, and even more efficiently

transfer the heat to the heat surfaces (large heat transfer coefficient

also called the k-value).

This indeed makes steam very attractive to use

for process heating, and on top of this, it is also a well defined

medium from which engineers worldwide have a lot of experience working

with.

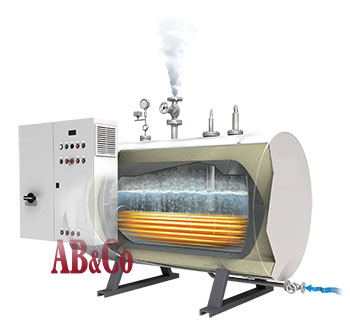

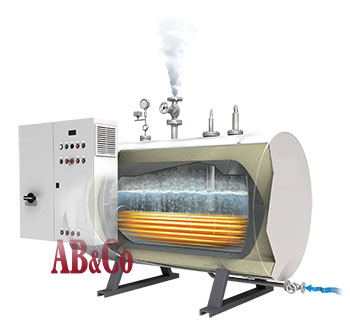

Steam Boiler

(oil/gas-fired)

Steam Boiler (electrical)

These advantages must be considered up

against some significant challenges when dealing with this high

temperature steam.

First of all, dry saturated condition

steam temperature correspond and steam pressure as it appears from the

thermal properties given in so-called steam table:

AB&CO Steam Table

AB&CO Steam Table

High temperatures saturated steam will always correspond high pressure

steam, and for some high temperature applications this pressure

needs to be extremely high to have the requested heat transfer.

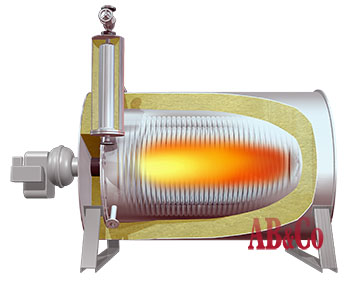

A solution for this is the steam boiler design known as steam generators, where the feed

water evaporates while passing through the piping of a multiple coils (one-through).

With this design it is technical possible to get up to 300°C which

require a steam pressure of 85 barg and a design pressure of nearly 100

barg.

The challenge here is not the steam generator, but the steam

system after. All piping, instrumentation, armatures, tanks and

consumers need to be design in a very high pressure vessel class and

becomes very expensive.

Steam Generator Boiler

Horisontal & Vertical models

(Oil & Gas-fired only)

Note that steam generators in this high pressure design are not

available in standard versions as electrical heated model, although

electrical steam boilers are wrongly often called

"electric steam generator".

Oil Replaces Water and Steam

So the pressurised steam or water

systems easily becomes very

controversial and expensive. However is that has been the situation for

centuries - and has thus been general accepted to deal with -

technically and economically.

There are actually alternatives - high temperatures does not necessary need high

operating pressures!

|

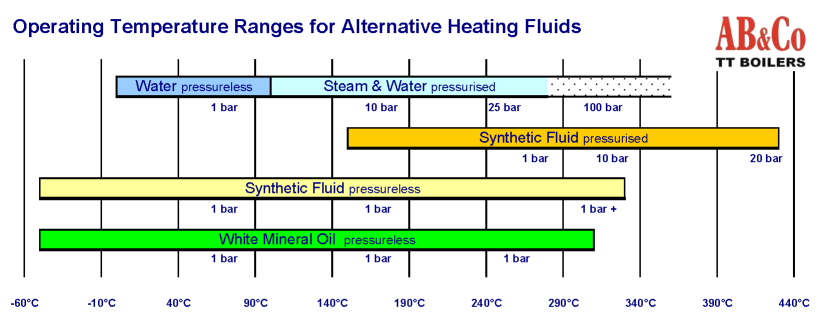

In thermal oil heaters a special oil - a so-called heat transfer fluid (HTF) are

used instead of steam as heat carrier,

and is operating at

atmospheric pressure up to

abt. 300°C.

For comparing this to water and steam, it would require a steam pressure of 85 bar to

obtain this temperature.

There are several advantages by using a thermal fluid (HTF) compare to

saturated steam.

The most obvious advantages are:

|

High operating temperatures -

up to 300°C at atmospheric pressure. |

|

Adjustable set-points of

operating temperatures. |

|

No equipment for pre-treatment

of boiler feed water to maintain. |

|

No heat loss due to hot

condensate and flash steam - high efficiency and better

operation economy. |

|

No risk of corrosion and no

risk of freezing damages. |

|

Low maintenance costs |

|

Quiet in operation with no

steam stroke or flash steam / condensate noise |

|

Easy to operate (does not

require

steam boiler certified staff) |

But there are also some important limitations in the use of thermal

oil heating.

Often it is advisable to use for instance steam instead of thermal

fluid for installation below ~ 500 kW and ~180°C (heat carrier

temperature).

Thermal oil heating systems eventually becomes quite expensive for

the small installations. When AB&CO deliver small thermal fluid

heaters it is typically only when temperatures up towards 200 -

300°C are required. Thermal fluid also requires a very special

design of the consumer (jackets, heating coils, heat exchangers

etc.).

An important detail in the thermal oil

heating systems is the heat transfer fluid (HTF) which is often an

oil-based fluid (based on natural ingredients or synthetic created). It

is like the blood in your your veins - and thus it plays a major role in the

total shape of the system.

Like any products, this fluid are available on the market in many

qualities. The fluid must be safe and reliable, not only as a brand new

fluid, but also after years of service. It takes an expert to

evaluate the options in choice of fluid since potential side-effects are

numerous especially with cheap HTF. A recommended fluid is this

low-fouling and non-toxic ABCO NF fluid. Opposite fluid distributed by

most oil

companies, which are mostly paraffin based fluid, - this fluid is partly

naphthenic based.

This offers two very important

features for a HTF : First it is more heat resistant (stabile) to

high film temperature (contact to hot heat surfaces) than pure paraffin

based fluid. Secondly the fouling when it eventually arise, does not

lead to deposits on the inside of the tube. Instead the cracked

molecules stays in the fluid and can be filtered out in strainer or

similar on-line cleaning arrangement.

Synthetic HTF are available on the

market also, although they are very stabile at temperatures up to 400°C

- they are normally quite toxic, and must be handled accordingly.

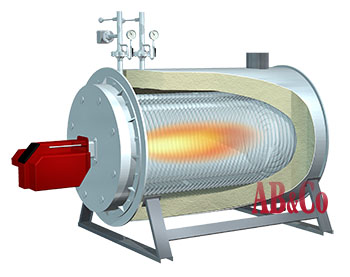

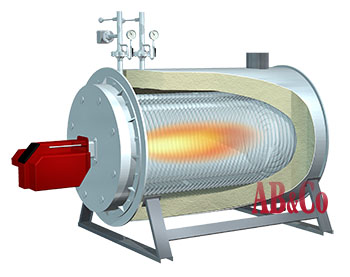

Design of Thermal Oil Heaters

Thermal oil heaters can be delivered in horizontal execution (with low

height), or in vertical execution (occupying limited floor space). They

are delivered complete, insulated and equipped

with burner, armatures, instrumentation, safeties and control panel -

and with full documentation including necessary certificates.

Thermal Oil

Heater

(oil/gas-fired)

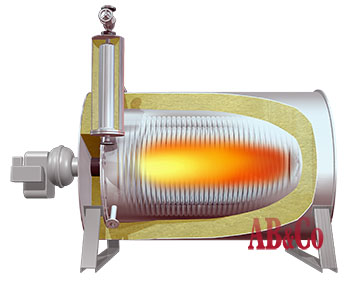

The

oil/gas-fired models are made with winded-up coils made of

boiler-certified tubes. The thermal fluid is

heated during the flow through the tube coil. The heat is transferred to the

HTF as radiant heat in the combustion chamber, where the inner

cylindrical tube coil and a flat tube coil forms the chamber walls and

the bottom respectively. Consequently refractory concrete can be

avoided. The combustion gasses are hereafter cooled in the outer

convection part, as the gasses are led between the space of the two tube

coils and the outer boiler shell - in another two pass.

|

The thermal

design with tube coils ensures a modest volume of the thermal fluid relative to the size

of the heater, and it also allows unlimited thermal expansion due to the high

fluid temperature.

The alternative electrical heated models

are also designed allowing a controlled and precise flow rate of thermal

fluid. This is done be multiple long vessels

with electrical elements welded in. The compartment with the elements

are furnished with baffle plates to

ensure high velocity and turbulent flow.

Thermal Oil Heater

(electrical)

As with any other industrial heaters and boilers today, the electrical alternative is

much

more attractive today than previously. Electricity has become clean and cheap in almost

any way. Taxes and duties is another story - a political thing only.

In

practical the capacities are typically below 1,5 MW since the electrical

installation rapidly becomes huge - for instance 1 MW requires a 1,600 A

electrical installation with voltage 3 x 400V.

Ensuring a Safe System with Hot Thermal

Oil

Thermal oil heaters and the complete thermal oil heating systems

should be designed and equipped according DIN 4754.

Both DIN 4754 and different EU codes (incl. PED 97/23/CE and

EN-standards) stipulate that the heaters must follow different

regulation including being designed as pressure vessels - and

consequently manufactured accordingly. This is required despite the

installation and operation are actually considered pressure-less (atmospheric)

and therefore not subject to all the special pressure vessel operation

requirements and maintenance practices & procedures.

Still the heater units must be provided with international recognized and high quality

main components, such as the electric heating elements or the burner for

natural gas, light fuel oil, heavy fuel oil or combinations (dual fuel).

All thermal oil heaters will be carefully checked, controlled and function

tested prior to dispatch from the workshop and are delivered with a full

set of documentation comprising drawings, diagrams, data sheets,

specifications, part list and instruction manuals. In EU the units will

be CE-marked accordingly.

A

correct and safe system design is very important for any high temperature

system. Therefore the requirements for the above codes and standards.

But safety must also be ensured by using only experienced suppliers for

other material, parts and components - and of course also the contractors for

building-up the whole system on site.

The engineers specialising in

thermal oil systems, knows about all those details - and they will

know about the features,

updated technical knowledge of possibilities, options, but also the

threats particular when dealing with these high temperature process

heating systems.

Even when the heaters

are of supreme quality in any details, the HTF inside is

still an oil. At high operation temperatures and insufficient design,

the HTF

can be fatal if not treated correctly.

It must be anticipated that the

local fire regulation codes must be strictly followed. It is highly

recommended that the local chief of the fire department is consulted

prior to projecting the thermal oil heating system - or changes in this.

Generally fire-preventing authorities can always shut-down any projects,

even though all regulations are followed !

Considering all above, it is therefore strongly recommended that the

chosen brand is from a experienced and well reputable manufacturer, and

that the system is made together with a professional and experience

supplier of these systems.

Do

never compromise in quality, it can be both fatal and expensive !

Thermal Oil Heaters

Options & Features

Beside the standard design, thermal oil heaters can also be delivered in

different special executions.

For instance following variations:

|

Electrical

heated and EX-design (ATEX) |

|

Flue gas (exhaust gas) heated |

|

Steam heated thermal oil |

|

Combination of heat sources |

|

Container solutions |

|

Open trailer (mobile) solutions |

|

Complete skid-mounted units |

|

Complete unassembled "LEGO" system |

|

Material in

stainless steel |

|

Any customised design |

|