AB&CO Container

Solution

|

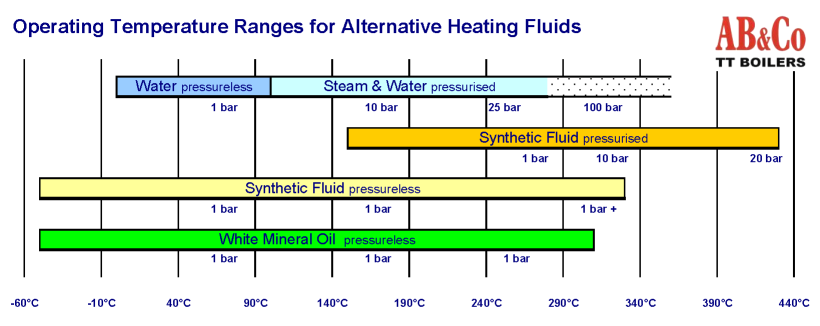

AB&CO Thermal Fluid Heating Systems are high temperature process

heating systems, using a special appropriate oil-based thermal

fluid, a so-called

Heat Transfer Fluid (HTF) as the circulating heat carrier.

These types of heating systems are used for high performance industrial processes - most often as an alternative to high pressure saturated steam. For instance spray-drying systems often requires very high temperature to achieve maximum performance. These

heaters become an attractive alternative

to the steam - mainly due to much higher operating temperatures

on the heating media (HTF), able to maintain low system pressure (often

atmospheric pressure).

There are numerous other

advantages for using this kind of heating, including

significant less overall operation costs. But there are also

disadvantages, See more at "COMPARE

STEAM AND THERMAL FLUID".

WARNING !

Despite the simplicity understanding the thermal oil heating system,

it requires experts with high skills to get all things right.

Unforetunately a lot of unsafe and poor designed systems are seen,

also that leads to severe and fatal situations. Being basically a hot oil,

it eventually burns when it is

not controlled 100%.

General Principle

|

|

AB&CO Large Package Solution

|

|

|

|

|

DETAILED DESCRIPTION

|

The

ThermoPack units (thermal oil heater units) comprise a heater,

pressure vessel, main pump, heat exchangers,

tanks, armatures, safety equipment, instrumentation, control system and the

tanks for expansion, dearating & de-gassing, buffer and emptying including

arrangement for filling/emptying system, barrels and tank. Environmental solutions are available in many alternative design - including mounting of economiser and thermal oil heated by utilising waste heat in, for instance, hot flue gas. AB&CO have

specialised in ThermoPacks as skid-mounted units and containerised solutions

(as shown on photo above / left). But systems are also delivered as separate

components e.g. the heaters alone (below photo) |

The simple principle in thermal thermal fluid systems is heating by use

of a special thermal

oil - also called heat transfer fluids (HTF).

AB&CO process air heat exchanger

These systems are all tailor-made and they are always delivered as complete packages for assembly on site, or as skid-mounted units when the size allows it. They come with full documentation and easy readable instructions for handling, erecting, installation operation and maintenance. |

SPECIAL

SERVICE

|

||||||||||

|

||||||||||||