|

Design

Gas-to-gas heat

exchangers (recuperators) are typically used for heat recovery of hot outgoing exhaust air / off gas -

and ingoing cold fresh air or process gas.

Applications are catalytic processes, industrial

drying, incineration plants (flue gas cooling).

They are delivered for low temperature applications (plate design) or for

high temperature applications (tube design).

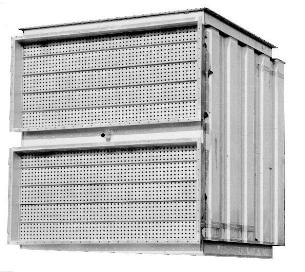

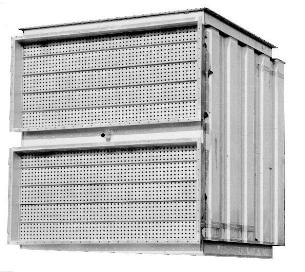

Ready for shipment. Two of the world's largest - each 2 x100,000 Nm³/h; 600°C (Haldor Topsøe,

Denmark with a weight of 36,000 kg / 72,000 lbs and with 33 km / 20 miles of stainless steel tubes - for heat recovery from

outgoing polluted exhaust gas, to heat incoming fresh air.

Totally eight of these types are

installed on exhaust gas cleaning plants in Denmark, Italy, Korea and Indonesia since

1995.

The units (photo above) were designed by AB&CO to

withstand a tropical hurricane (typhoon) placed in 18 meters height and at operating

temperature of 500°C. Six month after the installation, a very strong typhoon destroyed

a.o. large buildings and industrial plants in the area. When the hurricane was over, a

large 63,000 ton ship was found - blown right up on shore. But there was no damages

whatsoever on the two installed AB&CO Heat Exchangers.

Today these two heat exchangers are

up-graded 20% and still work perfectly, participating in cleaning discharge gas from one

of the largest chemical plants in East Asia.

120,000 Nm³/h; 550°C (Lonza/Alu-Suisse, Italy)

120,000 Nm³/h Air

heated by Flue Gas 650°C

(SamNam, Korea - Bakrei Kasei, Indonesia) |

Economical Process

Air Heat Exchanger

Plate Type Design

Heat Recovery Exhaust Air - Fresh Air

43.000 / 58.000 kg/h

(Netherlands)

Heat Exchanger for 1400

kW Heat Recovery

Plate Type Design.

Including Cleaning /Washing Arrangement (Netherlands)

Tools for Engineers |