|

ELECTRICAL MODULAR STEAM FOR DENMARK

For a large

pharmaceutical company with allergy research and treatment,

one of AB&Co's

famous modular steam boiler solution is being delivered. It

is a containerized solution with numerous special features

including 72 hours operation without surveillance.

Having a installed electrical power of approx. 1 MW the

solution will ensure a steam production of approx. 1,5 tons

per hour i.e. using clean green electricity, mainly from

Danish wind power.

STEAM FOR THE DIKES AT FALSTER (DENMARK) New steam supply for Bøtø pump station with the old Atlas pump from 1901. Today a museum, back then 120 years ago and up to 1967 - it was a part of a huge project drying out the Mill Lake, establishment of a extensive dike system and draining off the recovered land. This was done by a steam-driven pump. An economical steam generator has now replaced the old original boiler. More about affordable steam generators.

STEAM FOR FAROE ISLANDS

For steam back-up in certain

periods, this 3-pass fire-tube steam boiler is delivered to

power plant on the Faroe Islands in the north Atlantic - through a local

experienced steam boiler specialist with whom AB&CO have

worked with for several years.

THERMAL FLUID AIR HEATER FOR INDONESIA Ultra-large process air heaters using heat transfer fluid as heating medium, is being finished in the workshop. The heaters will be used in starch production as a part of a huge thermal oil heating system. It is the second time this Indonesian customer orders with AB&CO. More about high temperature process air heaters.

HP AIR STEAM HEATERS FOR AUSTRIA Six special steam heaters for high pressure air (PED) - ready for dispatch. The customer is a large and famous Austrian system designer of environmental process systems.

EXHAUST AIR HEAT RECOVERY FOR THE NETHERLANDS Air-to-Air heat exchanger for 1.400 kW heat recovery from exhaust air to fresh air - delivered for a large Japanese plant in the Netherlands. The recuperator is designed with a washing / cleaning arrangement for cleaning the heat exchanger on the exhaust gas side. More about gas-to-gas heat exchangers.

SPRAY DRYING HEATER FOR CHINA A new process air heater ready for dispatch - for the world's largest supplier of spray-drying plants to whom AB&CO have delivered these units for more than 30 years. More about process air heaters.

CLEAN STEAM FOR TAIWAN This special clean steam plant was delivered for a Norwegian shipowner building a fish factory ship in Taiwan. The clean steam is made by means of industrial steam and is used for fish processing. More about clean steam boilers and reboilers

ELECTRIC STEAM BOILER FOR DENMARK Ready for shipment to one of the largest producers in Denmark of poultry food. This customized model has a capacity of 280 kW equal to a production of approx. 450 kg/h saturated steam. More about electric industrial steam boilers.

CONTAINERIZED THERMAL OIL HEATER FOR DUBAI A local ship-owner operating oil tankers in middle east region, will now receive a 2500 kW thermal oil heater type L-VTO placed inside a container. The container can easily be place on deck and connected to heating coils in the tanks. More about thermal oil heating systems.

PROCESS AIR HEATER FOR INDONESIA This heater - ready for shipment to a large manufacturer of rice products in Indonesia - is designed for 300°C thermal oil (HTF) heating up a large amount of process air for spray drying. The heat exchanger is made with AB&CO special compound finned tubes, which make the unit very compact and still extremely efficient. More about high temperature process air heaters.

PROCESS HEATING FOR EU Electrical heating has become the environmental solution - also for process heating. The demand is increasing day by day. However mainly in Europe (EU + Norway + Switzerland) which is probably reflecting a sad fact about which countries and states using green energy, and who is not. More about Environmental Process Heat.

STEAM GENERATOR BOILER FOR TURKEY

Winded-up tube

coils are used for both thermal oil heaters and steam

generator boilers. This double winded coil is for a 2.500

kg/h steam generator boiler for Turkey.

AIR PREHEATER FOR SWEDEN A very large air preheater (note the man on the top) has been delivered to one of the leading system suppliers of complete waste combustion plants. About 20 large air preheaters have during the years been delivered by AB&CO to different municipal waste combustion plants all over Scandinavia. More about ultra-large air heaters.

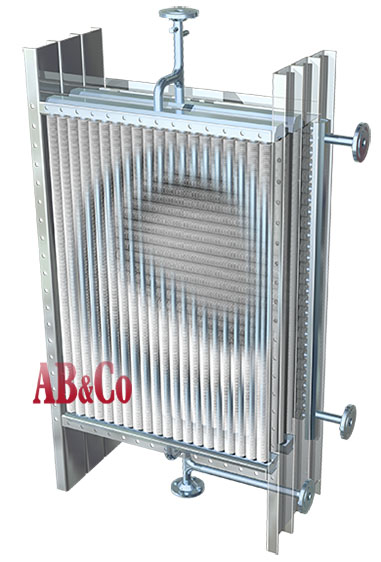

HEAT RECOVERY UNIT FOR THE NETHERLANDS The delivered heat exchanger is designed for heat recovery from hot exhaust air to cold fresh air, and is delivered to a major system supplier of egg powder plants. The housing is made of rigid stainless steel and the heat surface is made of high-efficient heat- transfer aluminum plates. More about Gas-to-Gas Heat exchangers.

ECONOMICAL STEAM BOILER FOR DENMARK The world's largest supplier of industrial catalyst plants located in Copenhagen, is now joining the group of customers of these economical electric steam boilers (/commercial models) used for their test facilities. Previously one of the largest breweries have acquired these models for their internal test labs. More about electric commercial steam boilers.

THREE HFO OUTFLOW HEATERS FOR PORTUGAL Ready for packing. Three special designed shell & tube heat exchangers for heating heavy fuel oil - place in the side of large fuel tanks. The units will be installed in a power plant in Portugal - using high efficient 2-stroke diesel engines to make electricity. The customer is the world's largest contractor of these kind of power plants and have during the years used numerous of these heat exchanger specially designed by AB&CO. More about special heat exchangers.

CLASSIC STEAM BOILER FOR SWEDEN Classic fire-tube steam boiler with capacity 2.2 ton per hour is delivered to the largest producer of flavors in Scandinavia. The plant is located at Malmoe in Sweden. More about small classic steam boilers.

Six special space heaters using 16 bar steam for space heating are delivered to Denmark's largest supplier of energy (private & state own company). Each unit deliver 50 kW and 5000 m3/h air. More about high performance air heaters.

FOR GERMANY The two high pressure steam boilers are delivered to one of the world's largest companies within production of industrial electro-mechanical equipment. The boilers are special designed with features complying with customer's demands.

HEAT RECOVERY FOR ANGOLA Loading of large flue gas recuperator. The unit will utilize the waste heat from incineration of oil sludge at oil field facility in Angola. The incineration of sludge oil is based on Danish technology.

LARGE NITROGEN HEATER FOR SAUDI ARABIA

ELECTRIC THERMAL OIL HEATER FOR CHINA For petrochemical plant in China this complete skid-mounted solution has been delivered. Capacity 250 kW and made in EX-proof design (equal ATEX).

HEAT RECOVERY FROM EXHAUST GAS FOR KOREA Air-to-air heat exchanger with tubes for heat recovery from exhaust gas to clean. Delivered to a Japanese company in Korea - through a Danish specialist in catalytic processes. Capacity 2 x100.000 Nm³/time; 600°C. More about Gas-to-Gas Heat exchangers.

HEAT RECOVERY FROM EXHAUST GAS FOR ITALY Air-to-air heat exchanger with tubes for heat recovery from exhaust gas to clean. Delivered to Italian-Swiss conglomerate through a Danish specialist in catalytic processes. Capacity 120.000 Nm³/time; 550°C. More about Gas-to-Gas Heat exchangers

ADVANCED ELECTRICAL SOLUTION FOR GERMANY

ELECTRIC AIR HEATER FOR INDONESIA AB&CO is now delivering a very large process air heater on 2,3 MW - for a major drying facility in Indonesia. 6 power stages ensures a complete capacity of 2,3 MW. That requires more than 3500 A at 3 x 440 V ! Not only Europe is going electrical, Asia is also very far implementing electrical process heating. More about electric process air heaters.

ELECTRIC STEAM BOILERS FOR HUNGARY

An old customer from

Hungary is now having another delivery of TT BOILERS customised

electrical solution. This time including a common 1400 kW power

board servinge the 2 x 700 kW steam boilers.

More about electric steam boilers.

THERMAL OIL SYSTEMS FOR POLAND & DENMARK Shipment prepared for the second thermal oil heating system delivered for totally two plants producing insulation material in Denmark and in Poland respectively. For each system AB&CO deliver one 6 m long exhaust gas preheater cooled by combustion air, two 6 m long exhaust gas recuperators cooled by thermal oil (HTF), one auxiliary gas-fired 1000 kW thermal oil heater in container and all accessories which is all skid-mounted on base frames for easy and fast installations. More about thermal oil heating systems.

SPECIAL THERMAL OIL HEATER FOR NORWAY

A complete thermal oil

heater unit with burner for fish oil is delivered mounted in

container for an application in Norway.

PRICE ATTRACTIVE STEAM BOILERS FOR SWEDEN

The product range of very

economical standard TEKNIK steam boilers have been extended to cover

also oil and gas-fired steam boilers and steam generators.

ECONOMICAL CLEAN STEAM FOR NORWAY For Tanager in Norway a TEKNIK 15 electric boiler 15 kW / 3,5 bar is delivered. Parts in contact with steam and base-frame is made in stainless steel. The solution is on wheels and equipped with steam hoses. This is a very affordable price-attractive clean steam boiler! The client is a producer of biochemicals, and needs to be flexiable in regards to both cleaning and heating application in the production line of their new factory in Norway.

LARGE HEAT RECOVERY

SYSTEM

3 (three) large flue gas

recuperator (heat exchangers) and a supporting thermal oil heating

system - totally 5 MW - is now shipped to the factory in Aalborg,

Denmark.

ULTRA-HIGH-PRESSURE

ELECTRIC STEAM BOILER For a major research institute in Switzerland, an electric steam boiler is delivered with a design pressure of 120 bar. The high pressure steam is to be used in an advanced test-bed in conjunction with R&D project concerning methods for production of environmental fuels.

|

AVOID THE HUGE HEAT LOSS IN STEAM SYSTEMS 10 - 20% loss of expensive energy and expensive special treated water, can be be avoided by a very simple heat recovery, that actually has a very short pay-back time.

DONATION TO UKRAINE

AB&CO have donated a 6-digit amount to the Red Cross

organization in Denmark for helping the numerous innocent victims in

the massacre in Ukraine since 2022.

GREEN ELECTRICITY IS THE FUTURE ! Throughout Europe energy is made by wind-power, solar power, hydro power and non-fossil fuels. Cars runs on electricity from wind power generated in the the night-time - and process heating is provided by electrical boilers and heaters. AB&CO is a leading actor in this huge environmental step.

Standing in front of the electrical company car, Marcus from the R&D workshop is carrying the smallest 6 kW standard steam boiler - on his left side you will find two 1 T/h electric steam boilers ready for dispatch.

Today you see a demand in the market for

electric steam boilers

:

The standard

electric steam boiler type K-DH is a range of small boilers

that in capacities goes from 2 kg/h up to 270 kg/h steam and

up to 10 barg. For such

application, it is recommended to use the customised industrial range

L-DH, that goes from 5 - 1500 kg/h steam and

pressure from 0 up to 40 barg.

So electrical

heating is the environmental way today - and that is easily

registered in the AB&CO order books for electric steam

boilers.

NEED TO BE AN ENGINEER ?

Here is step 1.

ACTIVITY IN THE

WORKSHOP

ENVIRONMENTAL PROCESS HEATING

Our business focus on

environmental process heating and heat recovery has for many

years been symbolized by our below logo, which you will find

everywhere in our material. This remind you ourselves about our

concern for the environment when designing the boilers,

heaters and complete process heating systems with high

efficiencies, heat recovery features and clean technology.

ISO 9001 : 2015 AB&CO has renewed the ISO-certificate for another 3-years' period. More about the ISO certificate.

"Expert company for main inspection of steam boiler safety and control equipment. Design, installation and start-up of steam, hot oil and hot water boilers as well as systems incl. repair, service and maintenance. Performing statutory inspections on pressure equipment"

EU GENERAL DATA PROTECTION REGULATION

Your

personal data registered at AB&CO is limited to the absolute

minimum enable us to forward a quotation based on a inquiry send

by you, and to book a order that you have placed with AB&CO

according to order confirmation.

UPDATED REFERENCE LISTS

AB&CO has updated

reference lists for 4 lines of key products:

FOLLOW AB&CO GROUP ON LINKED-IN We announce news from AB&CO on Linked-In. Join us, be a follower and get the news when news are news.

35 YEAR'S BIRTHDAY In 1988 AB&CO was founded. In 2023 it was 35 years ago. Obviously a lot has happened during the years, but customised process heating have been the key competence all the years - from design to manufacturing. More about the R&D Workshop.

OFFER FOR FINANCING YOUR PURCHASE AB&CO is now able to assist customer with support in case financing becomes a challenge due to the global bank situation. The official national credit fund in Denmark called 'EKF' can help in financing the purchase of AB&CO products. The arrangement is based on an individual evaluation of the customer and country, and will involve a fee for the financing. The fee will depend on the risk that is considered by EKF, but is normally below 5% sometimes down to 1% only. More about financing your purchase with AB&CO by the Danisk state.

CONSULTING SERVICES - HEAT RECOVERY

PROCESS AIR HEATERS For projects worldwide, an increasing amount of the special high quality process air heat exchangers, are now being delivered. The units are delivered to food processing plants and for chemical application covering everything from baking/cooking to conventional spray-drying. Especially steam and thermal oil is used for heating up the process air, but also dehumidifying is requested - particular for spray drying project in tropical / subtropical humid areas.

THERMAL OIL HEATERS

Thermal oil heaters of both

oil/gas-fired and electrical heated types are delivered in large

quantities worldwide at the moment. One single customer ordered 10

(ten) oil-fired types each 800 kW. A customer from China, within

textile processing plants, have through 8 months been ordered 6

(six) systems skid-mounted on a base frame - everything connected

plug 'n play. For this customer AB&CO is now manufacturing a 1400 kW

skid-mounted unit including a thermal oil heated steam boiler and

hot water heater on the unit - and of course a flue gas heat

recovery unit (economizer) for preheating process water.

STEAM GENERATOR BOILERS TAKES OVER For steam

capacities below 2000 kg/h the classic fire-tube steam boilers seems

to loose the battle against the compact steam generator boiler.

AB&CO supplies both types of steam boilers, but the demand for steam

generator boilers are huge, while the inquiries for fire-tube

boilers are modest.

CONTAINERIZED AND SKID-MOUNTED SOLUTIONS A very large part

of the boiler and heater solution delivered the last 2 years, has

been delivered either skid-mounted on a base frame with tanks,

pumps, accessories, piping and wiring - or build into a container.

AB&CO COMPANY

SPONSORSHIPS

AB&CO PREMISES The AB&CO domicile was changed a couple of years ago :

Baldersbuen 57 Remeber to use this updated address on all mail, papers and anything you send/ship to us, - or when you wish to visit us. Looking forward to hear from you or see you in Copenhagen sometime.

|

||||||||||||||||||||||||