|

||||||||||||

|

Some Few Examples Heat Exchangers since 1990 |

|

Shell & Tube Heat

Exchanger |

Exhaust Gas Coolers for Insulation Production |

|

Scrubber

condenser for Spray-Drying Application |

|

HFO Outflow heater for Bunker Tank Mounting |

|

Electrical Preheating of

Special Fuel |

|

|

|

High Pressure Jet fuel / Water

Heat Exchangers |

|

Condensator for

Collecting |

|

Steam Boiler heated

by Thermal Fluid

|

|

|

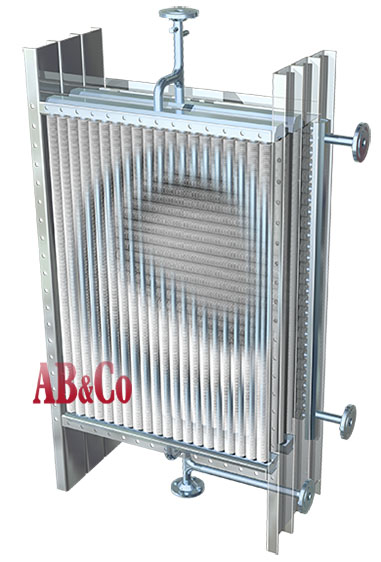

Process Air Heater |

Hexan Condenser

for Spray-drying Plant |

|

Full-welded Tube

Heat Exchanger

Twin

Tube Heat Exchanger for Chemical Industri

|

High Pressure Heat Exchanger with Full-access Tube Side Municipal Waste Disposal Plant (Denmark )  |

|

|

PROCESS AIR

|