PROCESS AIR HEATER

Indirect and Direct Heaters

|

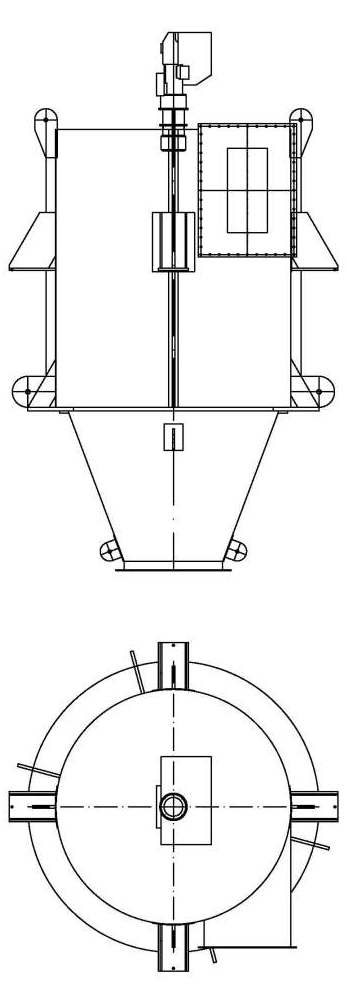

Type INDIRECT Process air heater can

also be delivered as indirect heaters in which a combustion chamber with

a burner is equipped also with a heat exchanger that transfer the heat

from the combustion gasses to the clean process air.

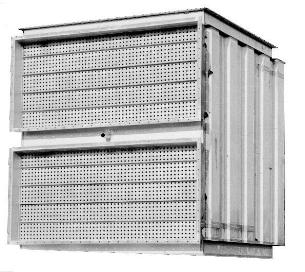

Combustion Gas - to - Process air heat exchanger (indirect process air heater). This units has a capacity of 120,000 Nm³/h process air @ 650°C installed at Sam Nam, Korea and Bakrei Kasei, Indonesia. Read more about gas-to-gas heat exchangers.

These direct and indirect heating of process air are alternatives to numerous other ways to heat up process air (using, steam, thermal oil, electrical heating etc) by process air heaters. |

|

Type DIRECT

The most efficient and

cheapest way to heat up air / gas is to have the flame of a burner in

the air/gas stream. This direct heating means that the combustion

exhaust gas is mixed with the air/gas. With this direct heating you will

be able to achieve very high temperature on the air/gas. However in

certain applications this cannot be allowed.

|