|

||||||||||||||||||||||

TOOLS for thermal engineers |

|

|||||||||||||||||||||

|

|

||||||||||||||||||||||

| INTRODUCTION | |

|

Flue gas / exhaust gas contains a large amount of heat. It comes from engines and these often produced flue gas at very high temperatures - or it comes from fired heaters where the flue gas temperatures is somewhat lower, but often the amount of exhaust gas is much larger. Instead of wasting the heat, the

boilers and heaters for heat recovery offer very good opportunities for utilising the

waste heat for production of steam, hot thermal oil or hot water.

Today process heat recovery

offers substantial economical advantages - due to reduction of CO2 and

saving the fuel. Furthermore heat recovery gives a good environmental

profile, that is required by many authorities and business contacts. The engineers of AB&CO · CONSULT and AB&CO · TT BOILERS have many years experience ensuring optimum solution for customers.

|

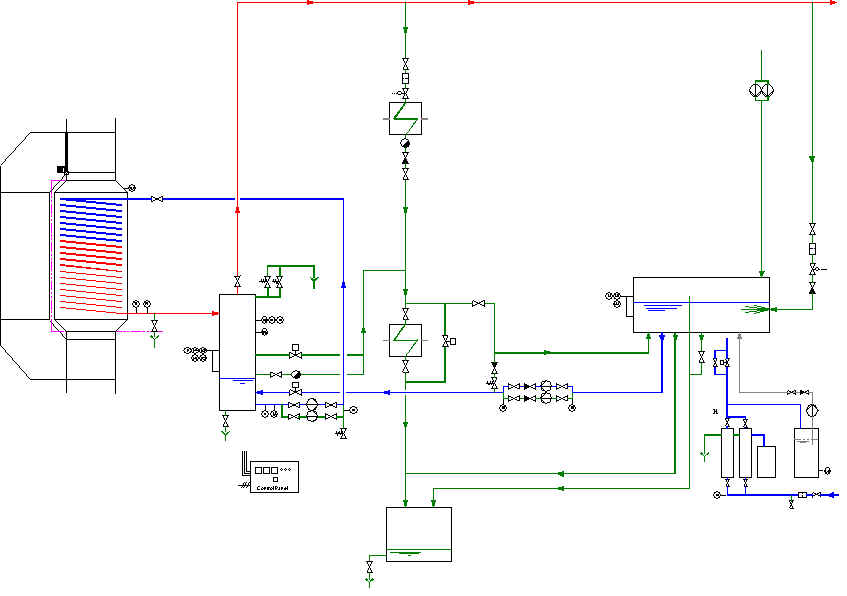

Heat recovery of process heat can be utilised in many type of heat exchangers - not limited to boilers as this chapter describe. Boilers and heaters for heat recovery, are also called economisers. Basically these are heat exchangers. The output depend on the size and design of the unit, but most of all it depends of the flue gas temperature, flue gas amount and the thermal properties on the other side. This means that the very hot flue gas from engines permits production of high pressure steam steam and high temperature thermal oil, while the colder flue gas from heaters and boilers only permits heating of water at moderate temperatures. Like heat exchangers in general, the same output the economiser can result in small and short, long and narrow, or big and width units. The design change from case to case. Below is an example of a heating system with an economiser operating as a steam boiler - a special economiser steam boiler system.

Economisers

installed on TT BOILERS thermal oil heaters

|

|

|

|

|

TT BOILERS Flue Gas Steam Boiler with by-pass |

|

|

|

|

|

|